Introduction:

Carbon fiber hoods are a popular upgrade for many car enthusiasts due to their lightweight, durable, and performance-enhancing properties. However, despite their strength, carbon fiber is not immune to damage. Whether it’s a small crack caused by debris on the road, a scratch from a careless car wash, or a more significant hole from an accident or impact, repairs may be necessary. While a replacement hood is always an option, many car owners prefer to repair their damaged carbon fiber hoods to maintain the vehicle’s look and performance without the expense of a full replacement.

In this comprehensive guide, we will walk you through how to patch holes in a carbon fiber hood. Whether you're dealing with a small hole or a slightly larger crack, this guide will help you understand the steps involved and provide practical tips for completing the repair effectively. But before we get into the nitty-gritty of the repair process, let’s first discuss whether patching holes in a carbon fiber hood is always a feasible option.

Can You Repair a Hole in a Carbon Fiber Hood?

The short answer is yes – you can repair a hole in a carbon fiber hood. However, the size and location of the damage play a crucial role in determining whether a repair is a viable option. Typically, smaller holes (up to about 1 inch in diameter) and minor cracks can be repaired successfully using carbon fiber repair kits. The process is relatively straightforward, and many DIY enthusiasts can perform the repair at home with the right tools.

That said, it’s important to note that carbon fiber hoods are not just about appearance; they’re also integral to the vehicle’s performance. Larger holes or structural damage may compromise the integrity of the hood and, therefore, its safety. In such cases, a replacement hood might be the best course of action, especially if the hole is near the structural support areas or if the damage spans a larger area.

For those looking for high-quality replacements, Revozport offers carbon fiber hoods that combine both strength and style, perfect for restoring the vehicle's performance and aesthetic.

For smaller cosmetic damage, though, patching the hole is often a suitable solution that can restore the hood to its original functionality and appearance.

Tools and Materials You’ll Need

Before diving into the repair process, ensure you have all the necessary tools and materials. Here’s a list of what you’ll need:

-

Carbon Fiber Repair Kit: This includes resin, hardener, and carbon fiber cloth.

-

Sandpaper (grit range 80-400): To prepare the surface and smooth out the repair.

-

Epoxy Resin: A strong bonding agent that will secure the patch.

-

Paint or Clear Coat: For finishing and ensuring a glossy look similar to the original finish.

-

Safety Gear: Gloves, goggles, and a mask to protect yourself from dust and fumes.

-

Mixing Tools: Small containers and sticks for mixing the resin and hardener.

-

Clean Rags: To clean the area before and after the repair.

-

Masking Tape: To protect surrounding areas from unwanted resin or paint.

Step-by-Step Guide to Patch the Hole

Step 1: Assess the Damage

The first step in repairing a carbon fiber hood is to assess the extent of the damage. Take a close look at the hole or crack. If it is smaller than 1 inch in diameter and does not affect the structural integrity of the hood, then the repair process outlined here should be sufficient. For larger holes, consult with a professional or consider a full replacement.

Step 2: Clean the Damaged Area

To begin the repair, you need to clean the damaged area thoroughly. Use a clean rag and some mild soap to remove any dirt, debris, or oils from the surface. Once cleaned, use a dry rag to wipe down the area. Ensuring that the surface is free of contaminants is crucial for a successful repair.

Step 3: Sand the Surrounding Area

Next, sand the area around the hole to create a rough surface that will allow the resin to bond more effectively. Use sandpaper with a grit range of 80-100 to roughen up the area around the hole, extending the sanding about 2-3 inches beyond the damage. Be careful not to sand too deeply or too aggressively, as this can damage the surrounding carbon fiber structure.

Once the sanding is done, clean the dust off with a clean cloth or compressed air.

Step 4: Mix the Epoxy Resin and Apply the First Layer

Now, you’re ready to start the actual repair. In your carbon fiber repair kit, you will have epoxy resin and hardener. Follow the instructions carefully to mix the resin and hardener in the correct ratio. Typically, this is a 1:1 ratio, but double-check your kit’s instructions.

Once the resin is mixed, use a brush or small spatula to apply the resin directly to the sanded area. Be sure to cover the hole and extend the resin slightly beyond the damaged area. This ensures a seamless patch.

Step 5: Apply the Carbon Fiber Patch

After applying the resin, it’s time to apply the carbon fiber patch. Cut a piece of carbon fiber cloth to fit the hole, ensuring that it extends slightly beyond the edges of the damage. The cloth should be large enough to cover the hole with a bit of overlap to ensure a secure bond.

Press the carbon fiber cloth onto the resin-coated area, making sure to eliminate any wrinkles or air bubbles. If necessary, apply a little more resin over the cloth to saturate it fully. Smooth the surface with your brush or spatula to ensure an even layer.

Step 6: Allow to Cure

Once the patch is applied, let it cure. The curing time will depend on the type of resin you’re using, but it generally takes 6-8 hours to fully harden at room temperature. It’s essential to give the resin enough time to set before proceeding to the next steps. Avoid touching the patch during this time to ensure no imperfections.

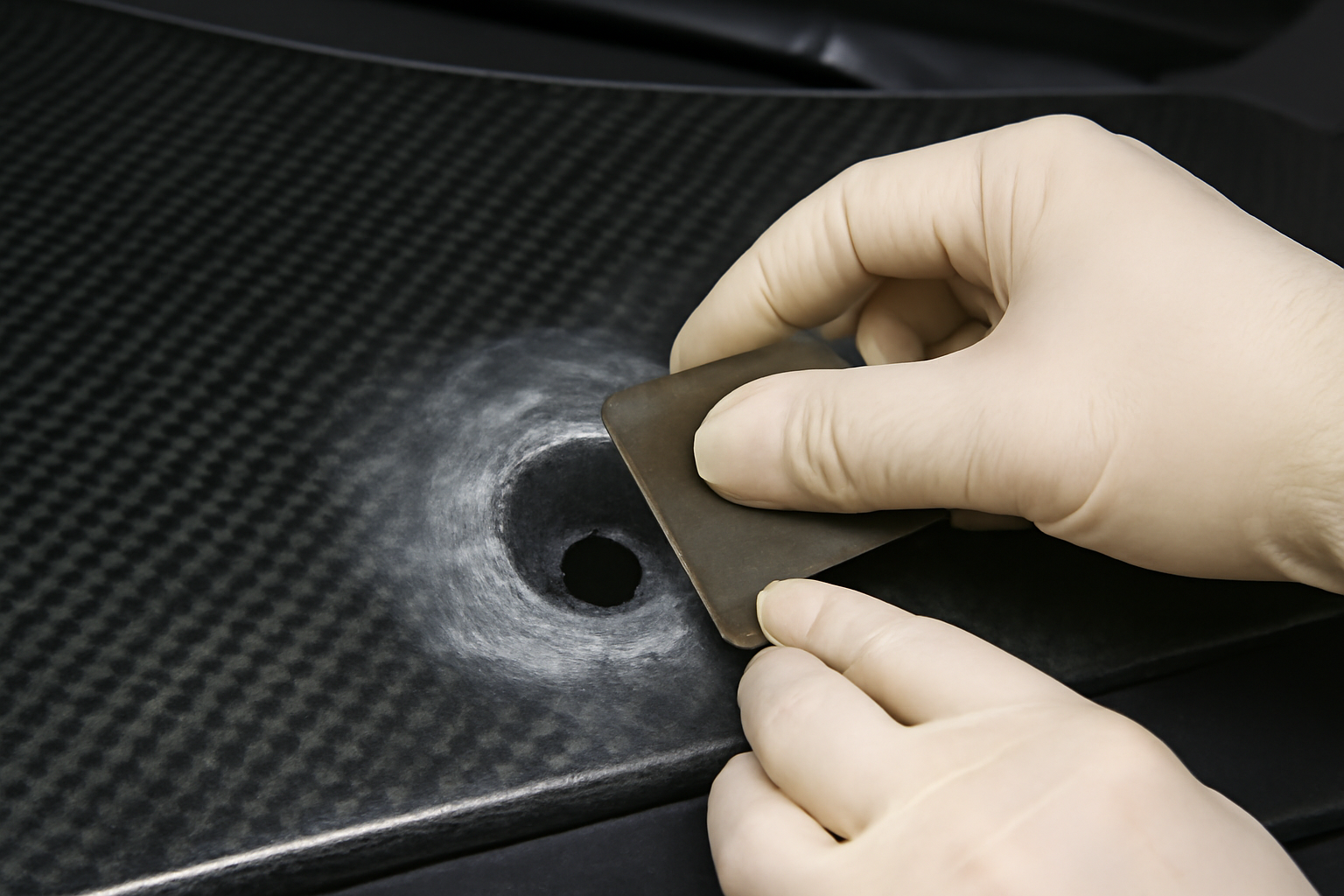

Step 7: Sand and Smooth the Surface

After the resin has fully cured, use sandpaper (around 200-400 grit) to sand the surface smooth. Be gentle during this step to avoid damaging the surrounding carbon fiber. The goal is to create a seamless, smooth surface that matches the rest of the hood.

Start with a coarser grit and work your way up to a finer grit to get the desired smoothness.

Step 8: Apply the Final Layer of Resin

Once the surface is smooth, apply a final layer of resin to seal the repair and protect the carbon fiber. Allow it to cure again as per the manufacturer’s instructions.

Step 9: Finish with Paint or Clear Coat

To restore the glossy look of your carbon fiber hood, apply a layer of clear coat or paint. This will give the repaired area a shiny finish that blends in with the rest of the hood.

Let the paint or clear coat dry completely before using the car. This final step will also add protection and prevent the repair from being exposed to the elements.

When to Replace Instead of Repair

While patching small holes in a carbon fiber hood is entirely feasible, there are instances when replacement is the better option. If the hole is larger than 1-2 inches, or if the damage is near the structural support of the hood, repairs may not restore the strength and safety of the original part. Similarly, if the carbon fiber is severely cracked or the damage spans across a significant area, a full replacement will likely be the best choice to maintain the integrity of your vehicle’s structure and safety.

Conclusion

Repairing a hole in a carbon fiber hood is a relatively straightforward DIY project for minor damage. By following these steps, you can restore your hood’s appearance and functionality while saving the cost of a full replacement. Just be sure to assess the damage carefully and use the right materials and techniques to ensure a durable and professional-looking result. For larger or structural damage, however, replacing the hood may be the safest option. As always, if you’re unsure about the repair, it’s best to consult with a professional to ensure the repair is done safely and effectively.

Reference

Share:

What is a Rear Spoiler for Cars? Understanding its Function, Benefits, and How to Choose the Right One

Spoiler vs. Wing: Which One is Right for Your Vehicle